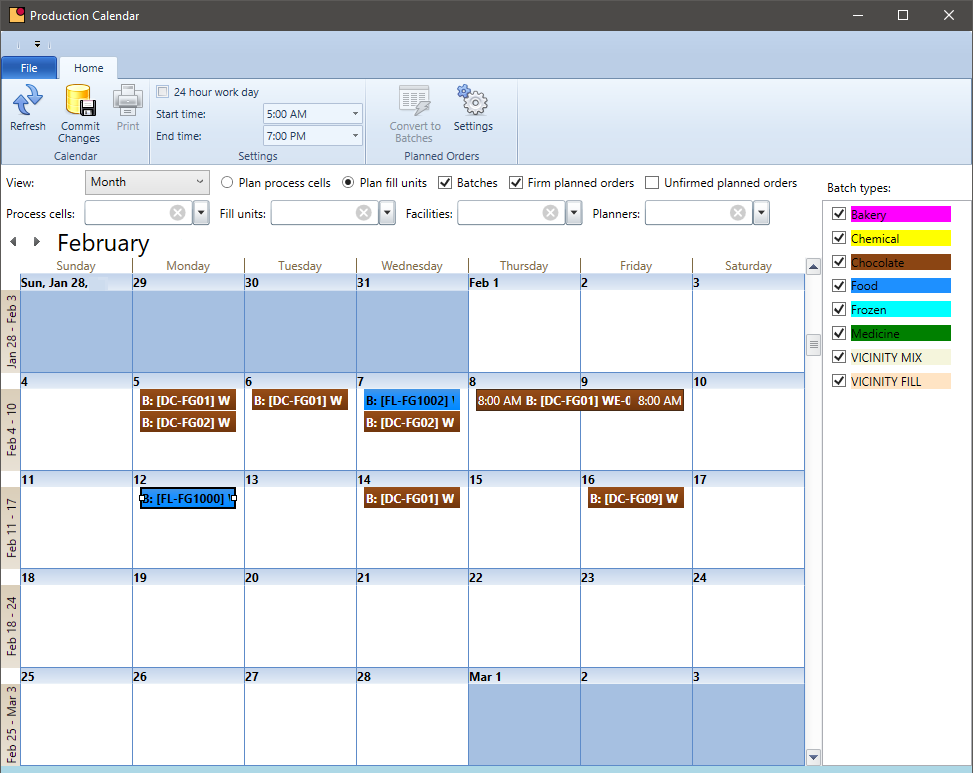

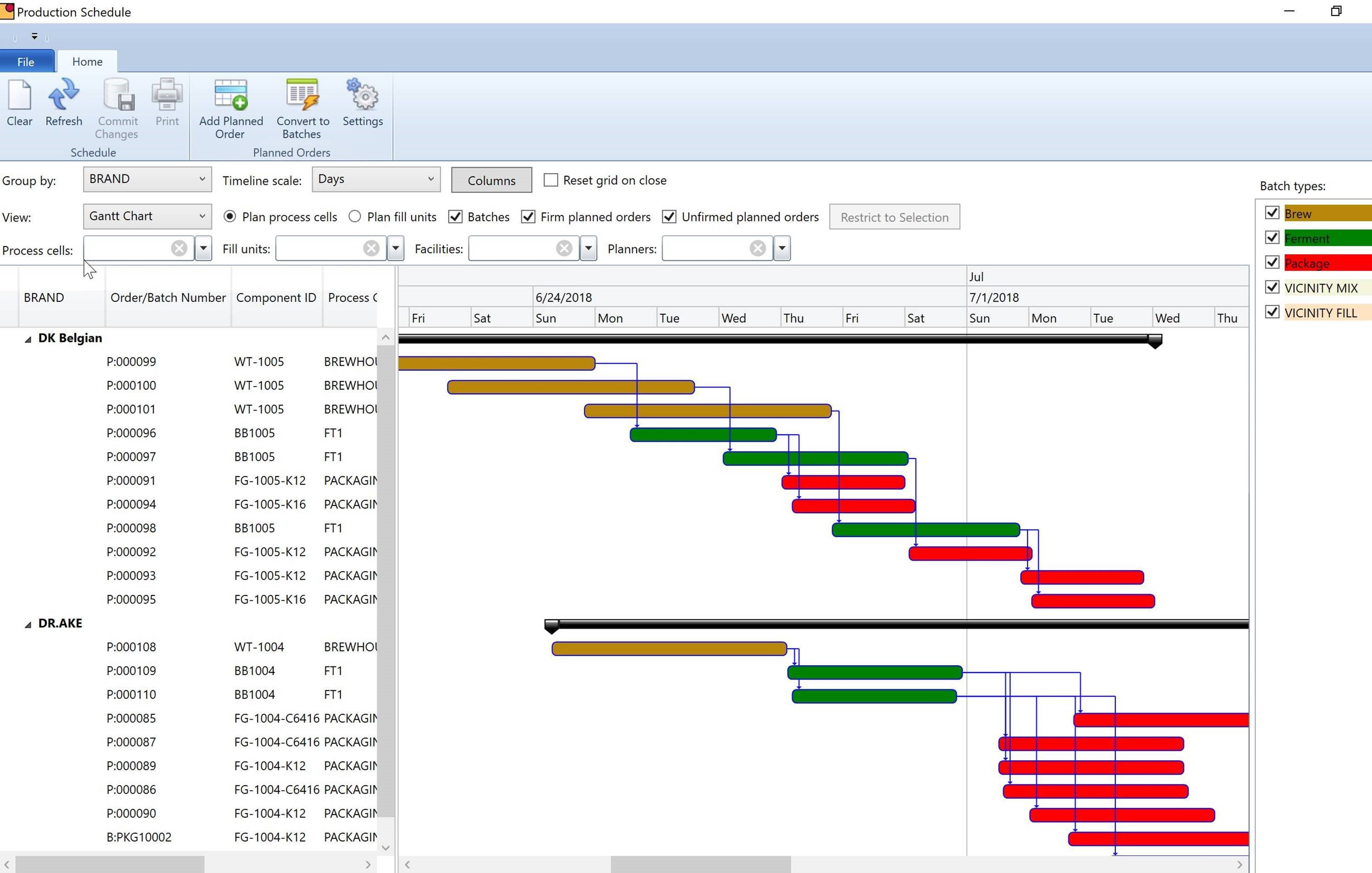

Visual calendar

How do you currently adjust your production calendar and how do you communicate it to others? Is it an integrated food MRP and batch scheduling solution or is it a stand-alone application?

Without a centralized ERP planning software, questions about the production schedule can cause delays in executing tasks across departments, or run the risk of changes not being communicated to the production floor in a timely manner. VicinityFood provides tools to manage the schedule as well as communicate with others. It uses tools that users are already familiar with to complete their tasks.

- Replace multiple sources of siloed information: Excel, Whiteboard, Google/Outlook calendar, etc. with one unified system

- Utilize dynamic, real-time data, shared in a centralized location across your organization

- Consider all known demand sources for scheduling with integrated, data connected sales orders and forecasts

- Streamline your production planning and batch scheduling to provide a complete picture of a facilities production outlook

- View the schedule in an interface familiar to all users - a calendar

- Move jobs from day to day with drag and drop functionality

- Isolate types of production or classes of products to better communicate the schedule efficiently

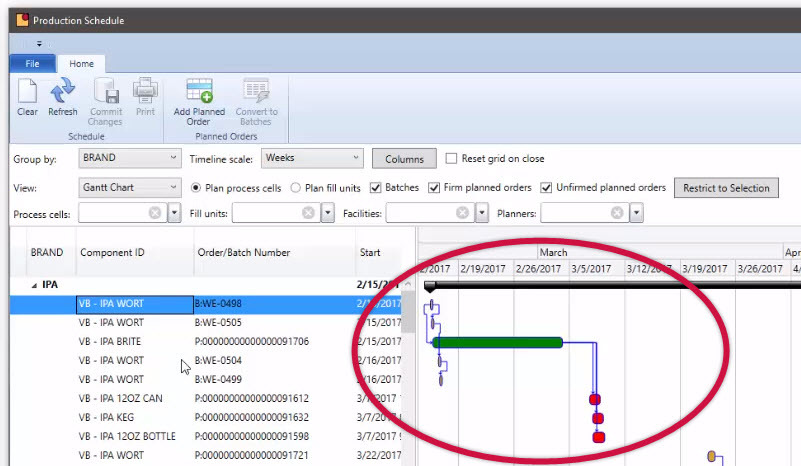

Schedule by Recipe

Are you forced to create multiple production records for end products that use the same recipe?

Without "batch" capabilities, food processors are forced to translate demand into a schedule manually, by cataloging all the products with the same core recipe, evaluate batch capacities to divide or size batches for optimal efficiency. VicinityFood is food MRP and food scheduling software that aggregates demand by recipe so a larger batch could be scheduled fulfilling multiple package sizes.

- Group production by brand or recipe to drive out demand at the bulk batch level

- Create multiple finished good items from one single batch ticket

- Bypass the creation of individual batches for each individual end item

- Blend holding tanks into a larger tank without additional effort

- View all batches on the schedule by recipe or groups of recipes

- Utilize a flexible unit of measure conversions from finished good items: volume, eaches, ounces, pounds, gallons, etc.

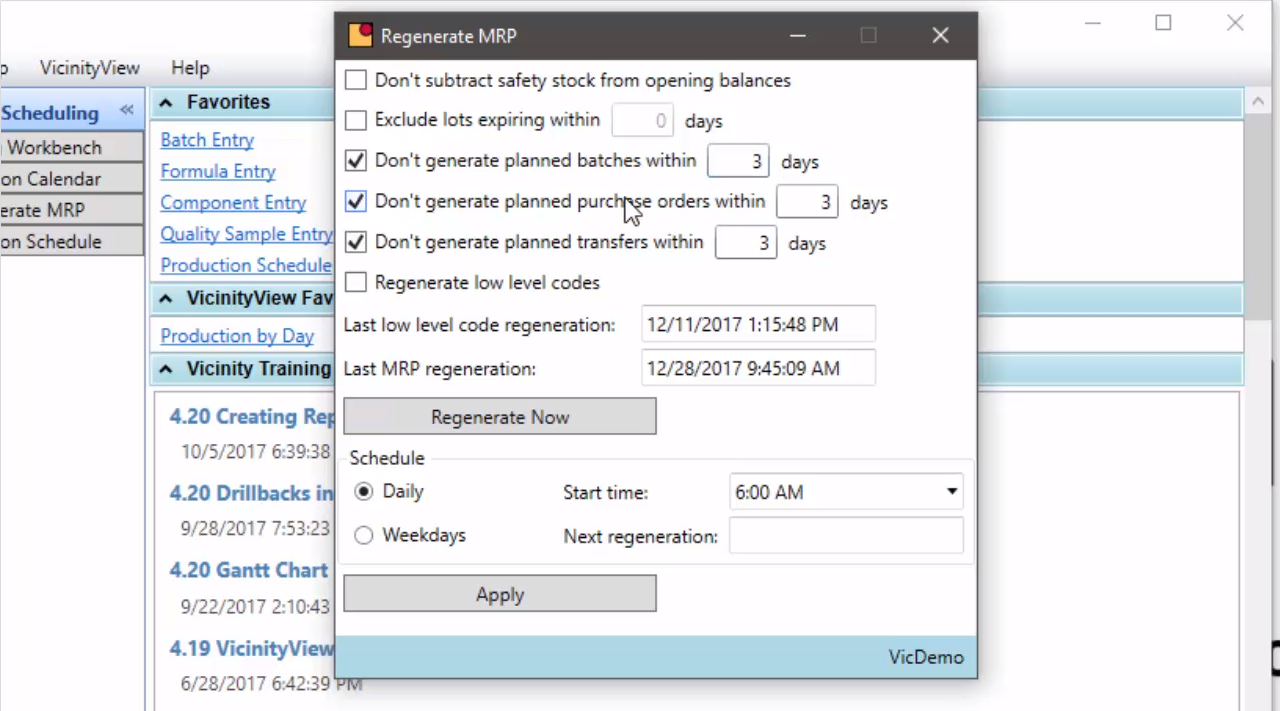

MRP

What process do you have to go through to determine what to make and what to buy?

Scheduling for food manufacturers needs to be precise, and manual processes can easily lead to miscalculations and other errors. If new sales orders are not incorporated into planning, your distribution center can miss shipping deadlines, or if items are double counted, your warehouse can be left overstocked with a particular item. VicinityFood brings all the data together and suggests planned production and purchase orders to satisfy anticipated shortages using a state of the art food MRP application.

- Reads sales orders, purchase orders, batch tickets, safety stocks, lead times and quantity on hand by date to use the most accurate and up to date data possible

- Nets transactions my formula, item and date to make reviewing the results efficient and intuitive

- Suggests production when a shortage is anticipated

- Utilizes production, purchase and quality lead times in suggesting dates to take action

- Provides unit of measure conversion to switch rapidly between weight, volume or each during analysis

- Schedule MRP regeneration during off-hours or on-demand

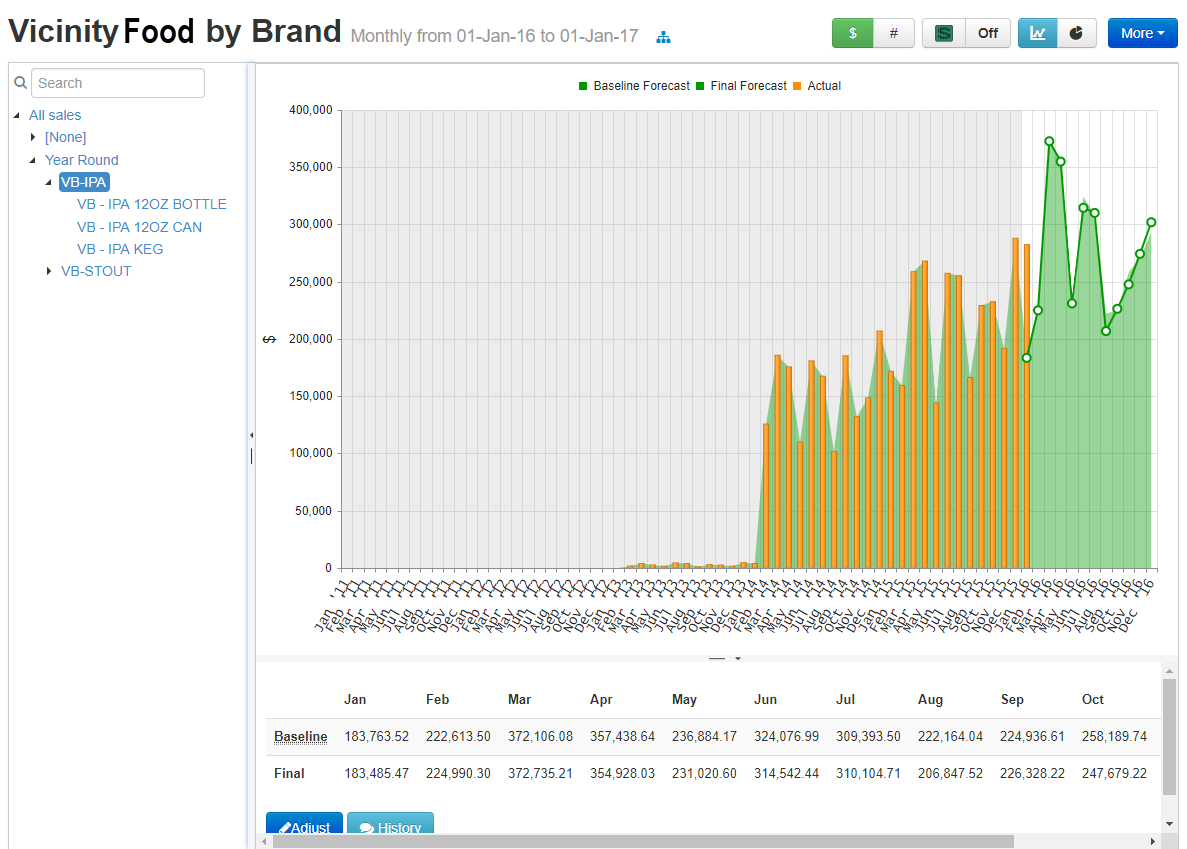

Forecasting

What steps do you go through to forecast sales today? It is a series of disconnected databases or spreadsheets?

For make to stock food manufacturers with short sales lead times and longer production lead times, a sales forecast becomes an important element to the planning process. VicinityFood has tools to help the planner incorporate the sales forecast into the production planning process. Whether you choose to forecast in your existing Excel spreadsheets or utilize one of a number of forecasting tools VicinityFood can incorporate that data into the database seamlessly.

- Forecast in existing Excel spreadsheets or use forecasting tools

- Include the forecast in the food MRP planning process in an automated fashion

- Automatically net sales orders to forecasts to eliminate duplicate demand

- Use flexible time ranges to forecast the way that is best for the company - weekly, monthly, quarterly is not a problem

- Leverage units of measure to forecast in a sales unit of measure (eaches) and plan in a production unit of measure (weight or volume)

- Update the forecast as often as needed

- Compare the forecast to actual sales to calculate and adjust for forecast error

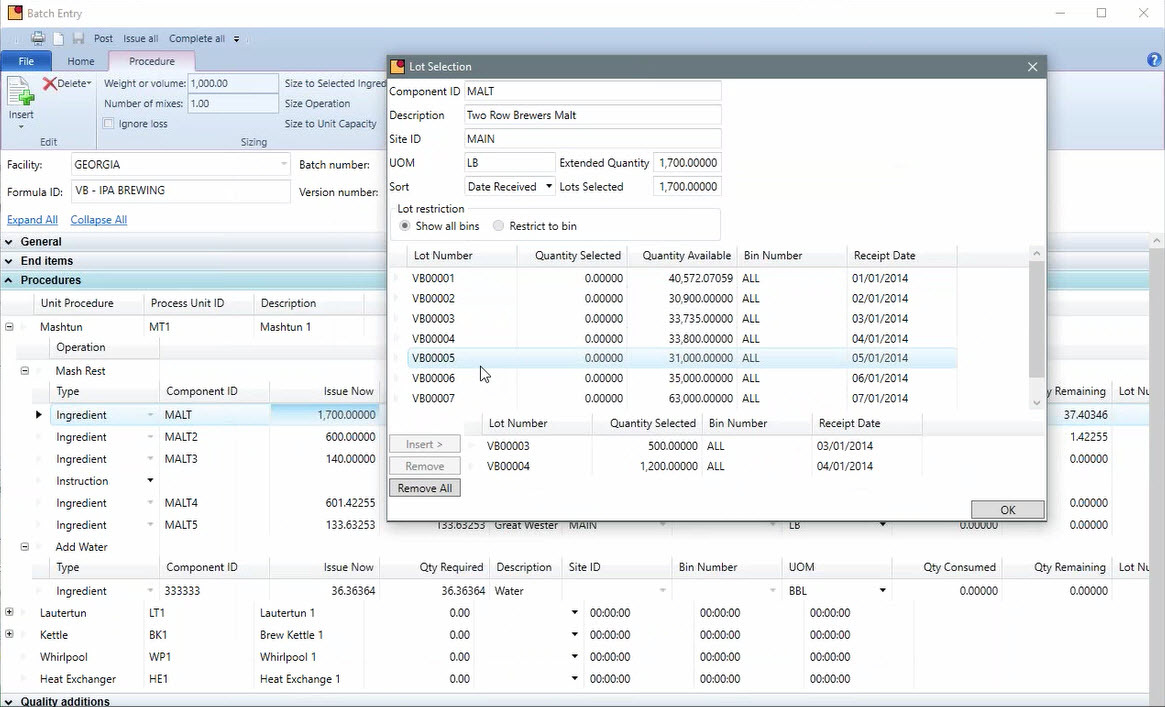

Lot rotation and expiration

How much effort goes into managing expiring lots and ensuring the oldest lots are sold or used in production?

VicinityFood provides real-time inquiry and notification as lots are about to expire, MRP can remove expiring lots from its calculations out into the future and expired lots can become unavailable for sales and production.

- Notify as lots are due to expired

- Suggest what lots are to be used on a batch ticket in order of their expiration date

- Calculate lot expiration date automatically for produced items based on the item shelf life

- Rework expiring lots into other batches to extend the shelf life and maintain lot trackability

- Indicate the number of days required on ingredient shelf life to reduce received near obsolete ingredient lots

- Identify lots to pick for sales orders - directing warehouse personnel to pick the oldest lots first

Schedule by production line

Is scheduling the shop floor time consuming with your existing system?

The production floor needs real-time updates on batch status' going through QC review, to stay on pace for shipping and distribution, or to take any necessary corrective action.

- Automatically notify your scheduling department about batches that are delayed or that fail QC testing

- Take any corrective action that is needed in a timely fashion