Food safety

Implement and manage food safety initiatives within your organization using centralized food quality control software keeping all employees on the same page.

Evaluate recipes via QC Results

Are you able to query batches based on a high occurrence of QC adjustments or lab calculations over time?

Food manufacturers can waste precious time by taking corrective action on a particular master recipe. QC observations over time or repeated quality adjustments can provide insight that a product is shifting from its initial specification and that corrective action is needed. Centralized food quality control software will help bring all users together around common data.

- Manage and track all test results by individual batch, recipe raw material item or finished good

- Review test results over time and the number of tests performed by a recipe

- Identify, analyze and adjust recipes requiring higher-than-standard adjustments effortlessly

- Target any of your products with a higher variability than others for review, resulting in a more streamlined and accurate process

- Implement SQF software and HACCP processes into the centralized system

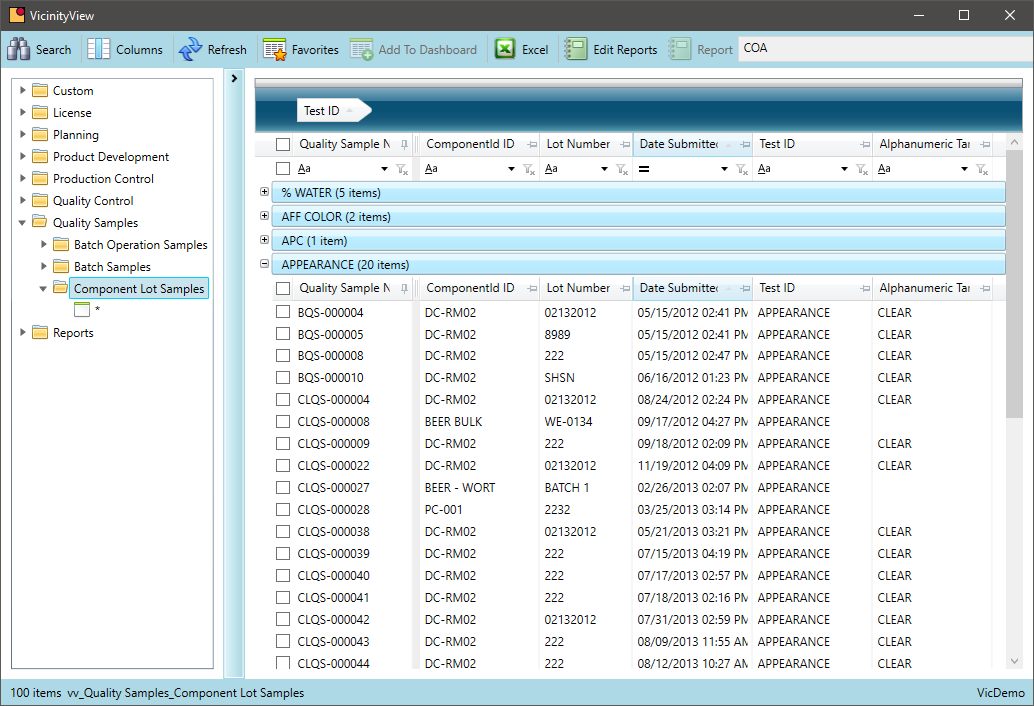

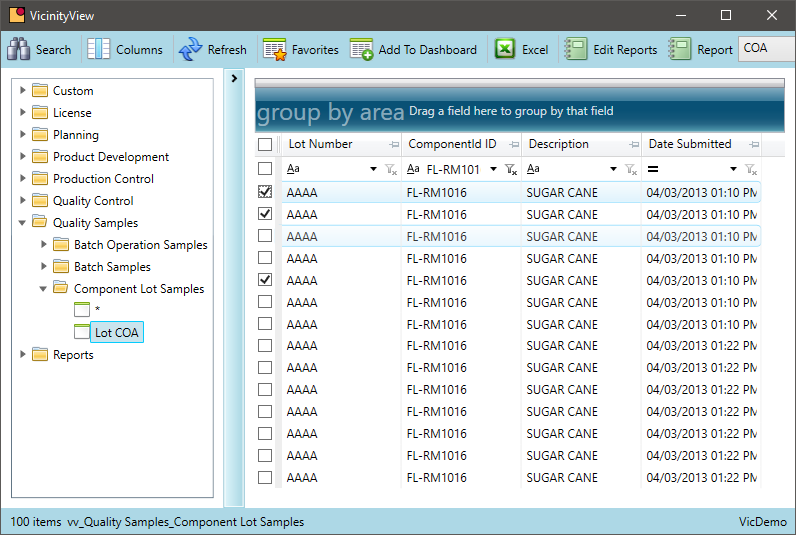

Accessible COAs

Can your system easily generate or access CoA documentation?

Having to depend on an outside department to create a CoA or simply reference source data can put a halt in your everyday workflow. Food quality software written specifically for food manufacturers will tie this data together and adding efficiencies in the quality department.

- Incorporate stored vendor Certificate of Analysis (CoA) to ingredient lots for future reference

- Generated and view the CoA with all subsequent records from QC results tracked by batch, recipe and ingredient lot on demand

- View and print CoAs for all lots on a sales order

- Set acceptable target values or parameters for each QC test

- Automate notifications for ingredient test results out of target test result ranges

- Initiate an approval process of lots available, or released, for use in production

- Identify, all recipes associated with an ingredient with the Where Used Report

- Evaluate the reach certain ingredients have throughout your product mix

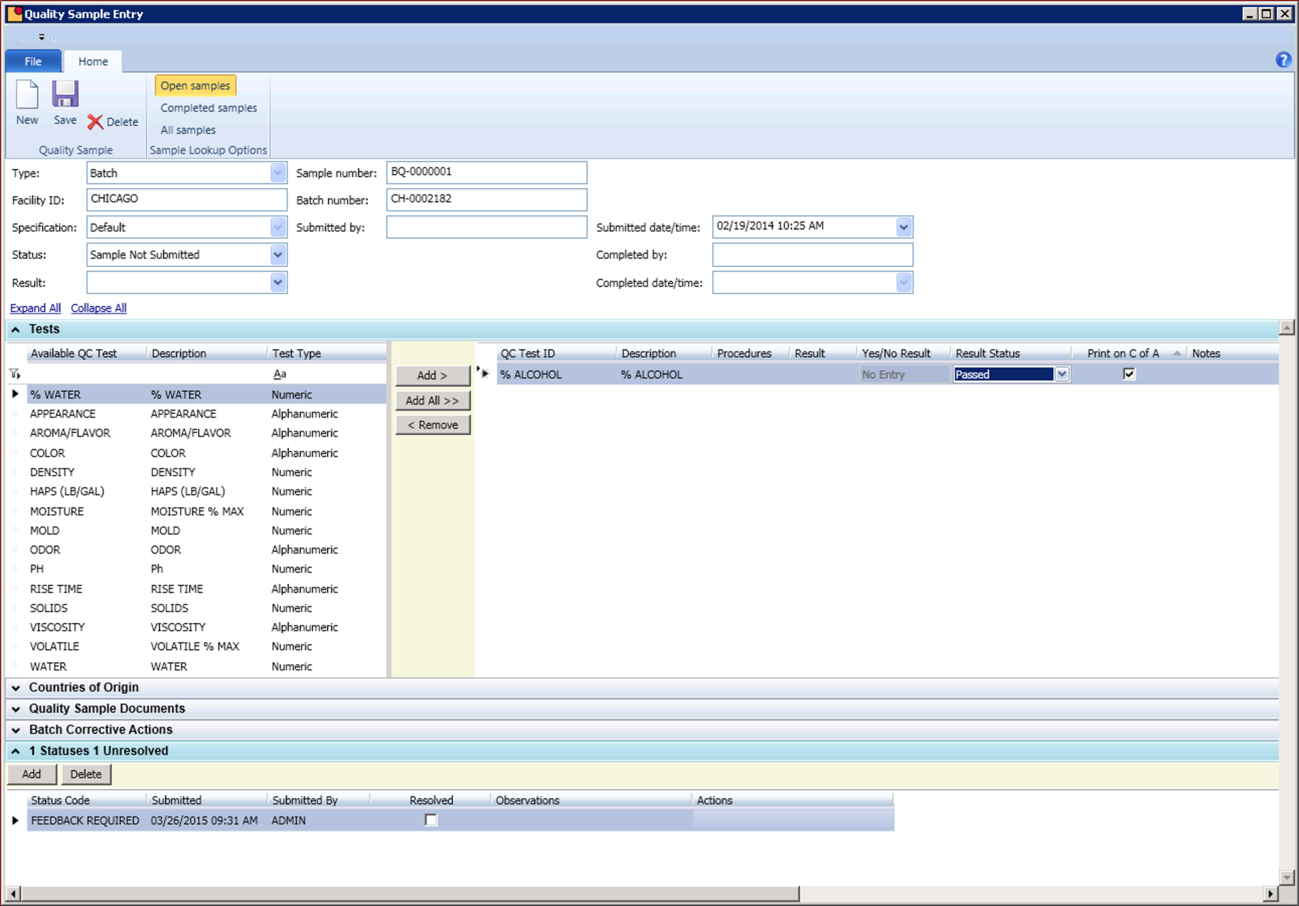

Integrated Quality Control Tests

Does your production team have access to consistent QC tests and protocol?

In the fast-paced food production environment, a test can easily be missed, overlooked, or improperly executed without clear guidelines.

- Print or incorporate all required tests on the batch ticket documents so they are available during data entry of the actual test results

- Copy tests automatically from the master recipe record as batch tickets are created

- Set acceptable target value or parameters for each QC test

- Choose from an array of QC tests from VicinityFood’s default library, such as pH, gravity, dissolved oxygen, Co2, micro-organism, daily tank checks, etc.

- Define an unlimited number of your QC tests including sensory data, notes and observations

- Associate specific tests to ingredient categories or add new tests on the fly as needed to individual items

- Correlate tests with designated batches

- Integrate to Genesis Nutritional Database to pull in nutritional values and calculate subsequent values of a whole batch

- Use the direct SQL to link to PowerBI, Excel, or use a custom built VicinityFood Quality Dashboard

- Tie your data to dashboards to visually highlight trends and evaluate test results

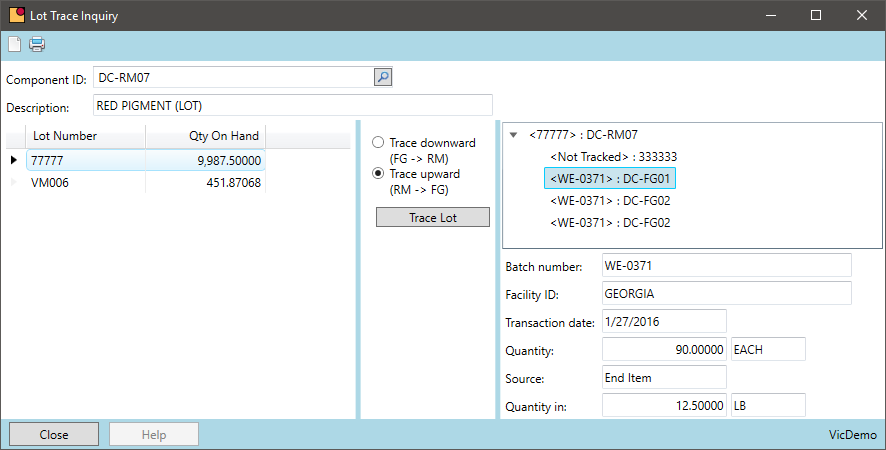

lot trace and Recall

What steps do you have to take to perform a mock or real recall of produced products or ingredients?

Food manufacturers are subject to regulatory requirements to demonstrate and employ reasonable recall processes on a moment’s notice. An important element of a food quality control system is lot tracking and integrated batch data. Pulling this together can be simplified allowing your staff time to manage the recall process.

- Lot track all ingredients and packaging that touches the product

- Record lots consumed and lots produced via the VicinityFood batch ticket

- Use the Lot Trace report to perform a lot trace from ingredient through production to the customer receiving the product as well as in reverse

- Demonstrate compliance as well as competence in food safety and traceability with the VicinityFood lot trace and recall functionality

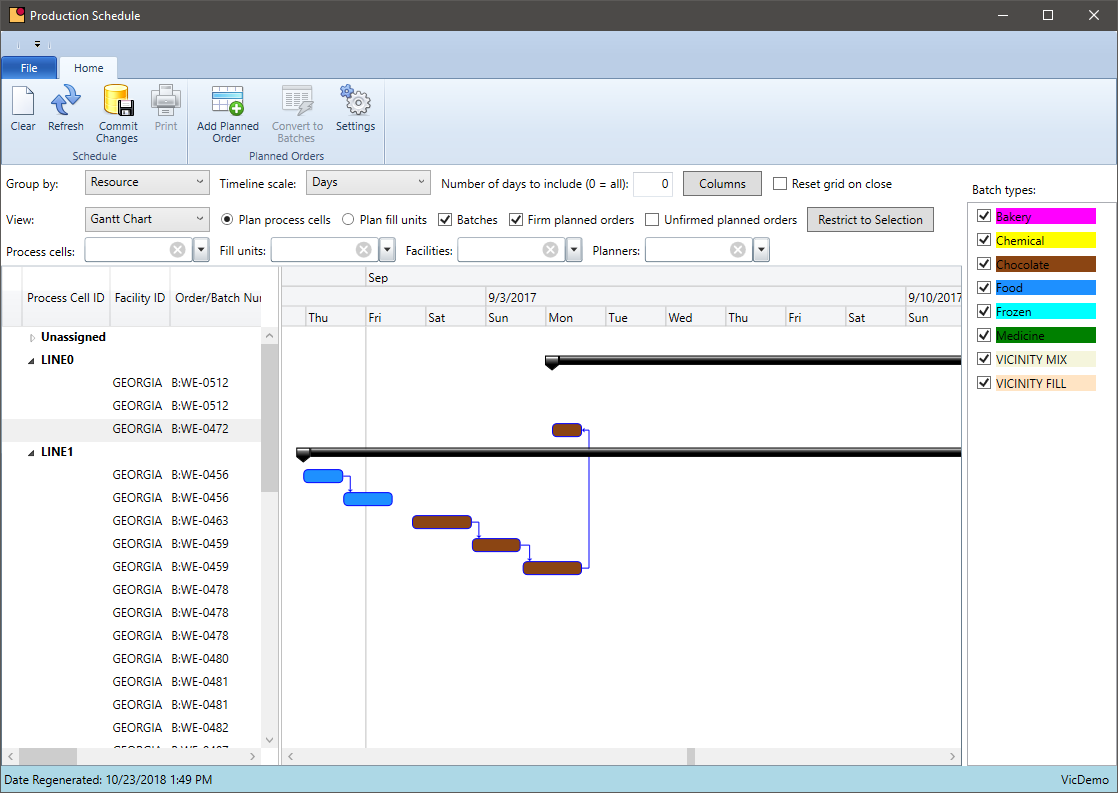

View Production Schedules

Are you able to plan out food safety initiatives to correlate with scheduled production?

In order to proactively plan upcoming taskwork and anticipate future food safety workload demands food quality departments need access to the schedule.

- View a real-time representation of the production schedule

- Schedule workload and anticipate required batch tests in advance

- Automate notifications of shortages or new orders not accounted for

- Investigate and navigate to an existing production log or create new production logs by simply double clicking