Evaluate Vendor Performance

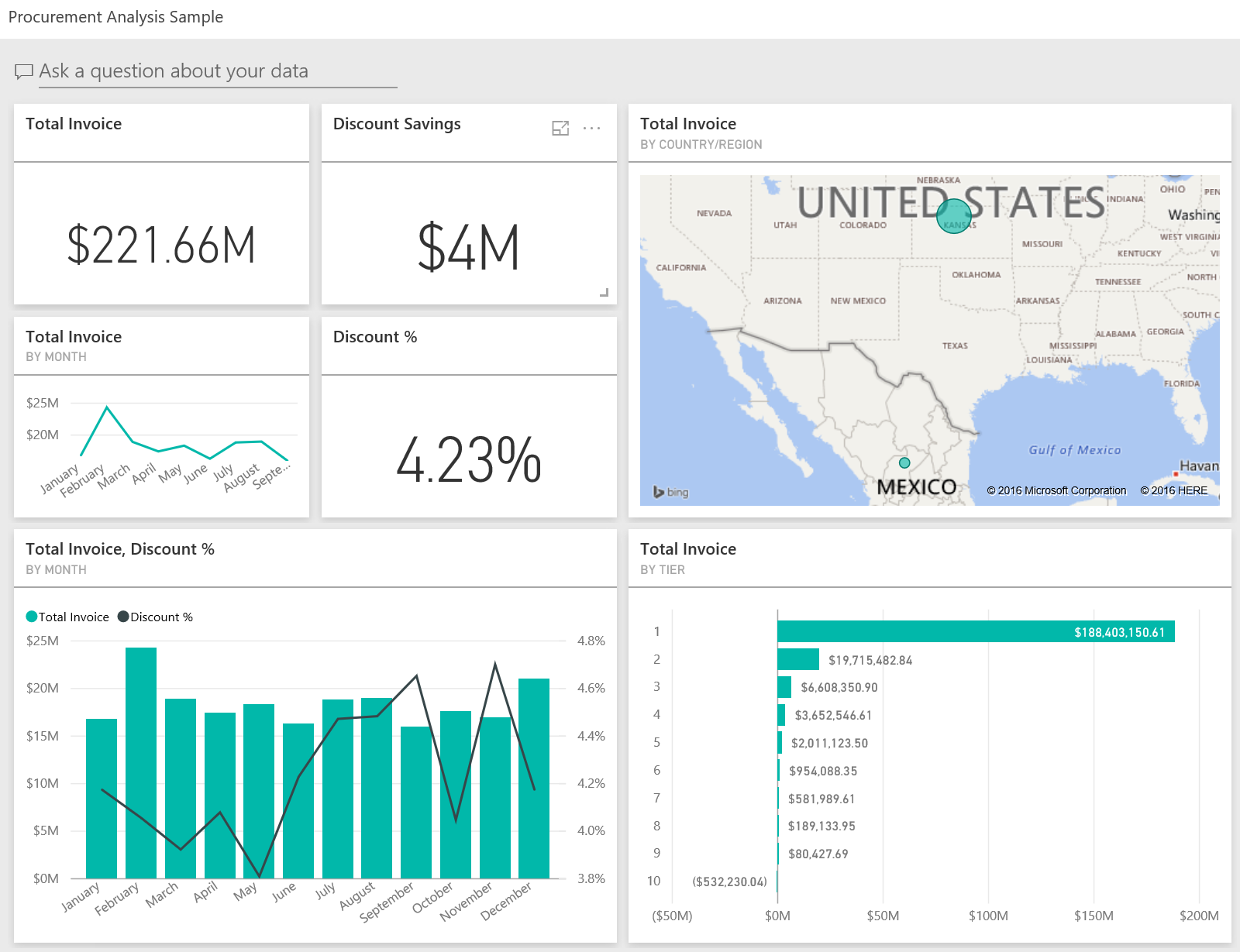

How are you assessing the performance of existing suppliers? What metrics are you using and how are you communicating the results to foster the best business relationship possible? Do you have a robust food supplier management software to assist your process?

Food manufacturers need an organized system to catalog vendor metrics so suppliers can easily be evaluated based on the performance or consistency of the product. VicinityFood ties purchasing, receiving, quality and price information together in one system to assist the user to make these judgments regarding food supplier management.

- Review QC tests results and observations by lot and vendor to use in future vendor evaluation including pricing and terms

- Manage vendor non-inventory activity with “interactions” tracking transactions such as site visits, sales calls, status’, etc.

- Use blanket agreement PO’s to manage contracted items at a set price with your vendors

- Utilize vendor PO’s to manage and streamline the receiving process

- Record stated lead times by the vendor to be compared with actual leads times on POs

- Utilize the MRP gross requirement calculations and communicate to vendors ingredient requirements in the future – Then compare their on-time and complete delivery rates to the information shared

Bar Code DatA collection

Has the volume of your transactions gotten to a point where an electronic data collection makes sense for your company?

Many food manufacturers process a significant volume of transactions that could be streamlined by introducing barcode data collection. Receiving of ingredients to movement into production, recording usage of ingredients and production of packaged goods, as well as shipping of customer orders, are examples where data collection could be streamlined. VicinityFood offers many options for barcode data collection each with a different set of features and designed for a different budget.

- Generate barcode labels for all inbound ingredients and produced items

- Increase speed and accuracy for repetitive activities like PO receiving, sales order shipping, recording ingredient usage, and product production

- Increase inventory accuracy by reducing the latency of data and reduce errors

- Reduce times for cycle counts or full inventory counts

Anticipate Shortages

Is your purchasing software able to anticipate raw material demand without overstocking?

Food manufacturers need a way to automatically convert the production schedule to raw material demand, this way more time can be spent evaluating vendors or discount opportunities.

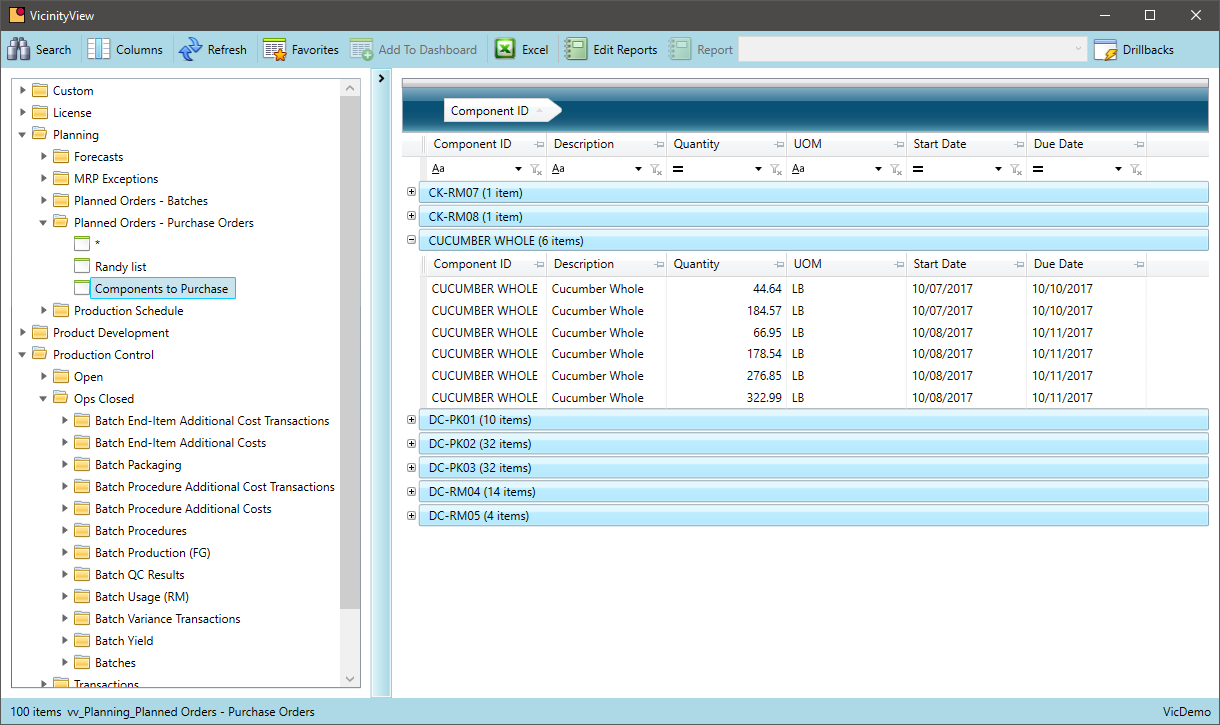

- Review anticipated raw material shortages based on a dynamic production schedule and real-time inventory levels

- Calculate shortages by item and day, considering lead time, safety stock and economic order quantities

- Reassess data routinely and create purchase orders for items and quantities from specified suppliers

- Manage inventory by exception and act on the items that need your attention

- Identify and automate PO suggestions on any necessary materials needed to meet anticipated demand, with Material Requirements Planning (MRP)

- Review all back-ordered products by distributor and by date with the Back-Ordered Summary Report

Available to promise

With a customer on the phone, is your system able to report the quantity available to sell after considering quantity on hand, competing sales orders and production on the schedule?

Food manufacturers are often in a commodity business where a commitment for delivery to a customer could make the difference in a sale. VicinityFood puts the data in the hands of customer service to see the current inventory position as well as future supply and demand of the item.

- Real time access to inventory on hand

- View into all sales demand for a specific item or items on an order

- Review the production schedule for anticipated production in the future

- Track batches in process seeing the status of production and if any quality holds

- Identify alternate items to repack to address an out of stock condition