Formula management, or having a thorough formula database software, is a critical element for batch manufacturers, both in production and R&D.

However, many process manufacturers don’t have this information integrated into their ERP system.

According to a study done by Aberdeen Group, 79% of manufacturers cited their top goal for the coming year as increasing profitability and marginal growth.*

As your business grows, balancing the demand for innovation while staying true to your product line requires many iterations for various formulas and recipes. The flexibility of a formula-based system enables the user to have tighter tracking, create multiple versions and reduce overall data input and set up.

Essential elements of a robust, integrated formula library include:

- A structured database to support variation and versioning of formulas

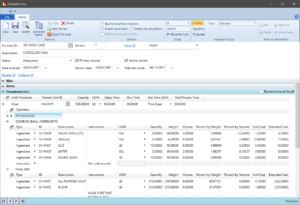

- The incorporation of key ERP data for R&D recipe development such as cost, inventory levels, and usage data

- An ability to easily search and query formulas based on set criteria

Standardized Structure

Formula development rarely starts from scratch; most new recipes live on an existing structure. Without having this structure supported by your production system, creating new items or testing variations of a formula can amount to a ton of data entry, which can result in these trials being left out of the system entirely. The absence of this information in your manufacturing system leaves your organization at a disadvantage when it comes to measuring how different trials perform in comparison as well as the ability to quickly transition trials into full-scale production.

Connect ERP Data

Being connected to ERP data is not just about the ability to review associated information, but rather, having direct access to the most current data to evaluate. As a customer request comes in, this may require new formulation or a formula revision, wherein R&D needs to measure the latest cost, inventory levels, and usage data to best assess the appropriate impact and provide a timely, accurate quote.

According to a study done by Aberdeen Group, 69% of leading manufacturers have integrated intelligence into their ERP.*

Formula Search

For both R&D and production, the ability to easily access and review existing formulas is a critical need. Instead of sorting through a paper lab notebook or house built database, companies need a powerful query tool to support multi-level search based on explicit criteria, such as the quantity of a specific raw material, allergen, hazard type, quality specification, or any other user-defined attribute.

Having this data readily available in a batch manufacturing solution can save you from the unnecessary setup in formulating new recipes with similar requirements as existing recipes, streamline your reporting and analysis efforts, and improve your ability to respond to items requiring corrective action.

Contact us today to learn more.

Citations