Watch and listen to the podcast presentation here.

Thanks to Dave Fusaro, editor of Food Processing Magazine for chatting with us. In this podcast, Randy Smith, CEO & founder of Vicinity Software will explain why there’s more to lot trace than lot trace.

Beyond Compliance: There’s more to lot trace than lot trace

June 2, 2022 Webinar

Food Processing Magazine

Food processors know how critical lot trace is, but the right software should do more than just tracking, compliance and auditing. Learn how to add in quality and how that is necessary to see stabilization within the manufacturing process — as that is tied to everything from the start to finish of every food and beverage product. See how ERP ties into other parts of the manufacturing process such as vendors, materials, data, and more.

In this webinar you will learn:

- Why lot recall and traceability is imperative in today’s marketplace

- How to leverage quality control throughout your manufacturing process

- How to better understand manufacturing through the eyes of quality

- Why leveraging an industry-specific ERP is a must for food & beverage manufacturers

Podcast transcript:

A brief overview of Vicinity Software and VicinityFood:

“We integrate with Microsoft Dynamics products and we handle basically all the scheduling and batch processing, formula management compliance type operations allowing Microsoft Dynamics to handle the financial and distribution. So we are very vertically focused.

We’ve been doing this for about 20 some odd years. We also have a QuickBooks platform for those not ready to go to a larger ERP system. In that case, we basically take over the distribution and QuickBooks handles GP and AR. So, we have a lot of background in the food space, specifically with bakeries and flavor companies, confectionary sauces, beverage meat processing and anybody who uses a recipe or formula in the manufacturing process is somebody that would be a good candidate for looking into our application. Today we want to talk a little bit about lot trace and take a look at traditional lot trace, but also with a twist.

First, let’s go through some of the benefits associated with lot trace. The obvious one is going to be regulatory compliance. Most of us in the food space are required to trace the lots through our manufacturing process from the supplier all the way through processing out to the customer. That’s pretty typical, pretty normal; different people have different requirements based on the potential danger or problems in the process, but there are other benefits as well associated with tracking lots.

And one of them that may not be quite so obvious is it really does increase your inventory accuracy because you’re spending more time dealing with it. I clearly agree that you’re going to take more resources when you add lot trace into your information system, but at the same time you’ll have better visibility, more accurate information. And in the long run, I believe it will pay off. It may not look that way initially, but over time that accuracy and being able to reduce inventory levels because you’ve got more accuracy, I believe will actually pay big dividends. Additionally, some of our clients have actually been using not just lot trace, but their information system in general, as a method of customer relationships with attracting new customers.

We actually have some customers that demo our software to their prospective clients. They have an understanding of how they’re handling information through their organization, from scheduling the quality to various compliance or reporting that they might need to do to the customer CS and things like that.

So being able to see and demonstrate this, improve this, and whether it be an actual or a mock recall actually pays dividends that you might not have thought about. There’s also another underlying and connected data.

Everybody’s got pockets of data through their organization to connect that the lot trace can actually become the glue for that. We’re going to talk more about that. And that’s actually the twists that I want to talk about through this before we get into any of that just get on the same page with each other on the transactions that are required for lot traceability.

And it’s not insignificant. I will readily admit that adding lot trace specifically and in an automated system like ours, it will take some change. It will take different information being captured at different times. Maybe different people must be doing some different roles to be able to facilitate it.

But if done right, those additional resource requirements can be absorbed throughout the organization. Different people will be doing different things. Now each of these transaction types need to be looked at individually. How am I going to handle raw material receipts? That needs to be looked at independently from say a warehouse transfer.

The information that you’ve got going into that raw material receipt is going to be different than the information that you’ve got for recording against the batch ticket. So for example, a PO receipt, when that PO is going to be coming in within reason, but you don’t know the exact time that it’s going to be coming.

So, there’s going to be a little bit of ambiguity as to when that product is going to show up. When you’re recording it against the batch ticket, you’ve got more certainty. So, you can do more planning and you can get prepared for recording of that information and using that information. So, my point of all this is to say, you really have to look at each of these transaction types independently and try to find out what it’s going to take to be able to do that lot trace either manually or through the system.

For example, for an inbound raw material from a supplier, you need to ask yourself the question, “what lot number am I going to use?” For example, the vendor probably has a lot number identified on the packaging and/or that packaging slip and do you use that lot number? Do you use your own lot number?

I personally believe that companies do better if they have a cross-reference. In other words, they keep their own lot number sequence for their own system and then have a cross-reference to that vendor lot number. In our case, in our system, there is a field that you can put in vendor lot number and we just apply and provide the next available lot number.

It’s a little more complicated than that because we have some configuration capability where you can have different sequences of lot numbers depending on the product, et cetera. But generally speaking, the system is providing a lot number on the inbound raw material. Then the next thing you got to be thinking about is what do I need to do to help the further steps, the next steps.

So, I did see what is going to help that warehouse transfer? What’s going to help the recording of that lot to a batch ticket? The obvious example there might be a label that gets to a scenario when you do a PO receipt, incorporate the generation of a label and applying the label to that inventory as quickly as efficiently and as real-time as possible so that the next transaction has all that information ready to go. And it kind of gets back to the point of using your own lot numbers. One of the big reasons I think that’s important is when the warehouse person is coming, looking for that particular inventory. If you don’t have your own label or your own identifier on it, it’s going to become a lot more time-consuming and complicated for that person to figure out am I supposed to be looking for a 12-digit lot number or a five-digit lot number? Do they put it on top of the box side of the box? Is it on label, et cetera? So, it just gets rid of that ambiguity. So, as you start looking at each of these steps, think about who will use that information. And where is it going to be going after this? if you’re going to be using barcode data collection to help with this, by the way, by no means, do you have to. Basically, a barcode is nothing more than a font where you’ve got the lot number, probably the item number, et cetera.

You’re going to want your own label for that rather than trying to scan somebody else’s barcode. That’s just way more time-consuming than printing of a label whatever that entails. So especially if you’re going to be barcode data collection, go ahead and apply your own label on that packaging. Now I’d like to also discuss a little bit about the next steps particularly about a warehouse transfer or in consumption of raw materials into a batch. There are some instances in which you’re going to want to assign or identify a lot before anybody goes looking for inventory.

It’s called directed picking. Where your picker is being told go find this specific lot. That may be because there might be a lot expiration issue coming up. There may be an attribute associated with that lot, like a bricks content or a water content that would particularly work well in this formula or this batch.

So, you may direct them to a specific lot to be done. That means whatever document you’re giving the warehouse manager or the person picking would also have that lot number on it. So you need to think through, at what point do I identify the lot, and who can identify that lot? How can I communicate it to the person picking? And then in consumption we talked just briefly about using barcoded this process, I’m a big fan of barcode data collection for that raw material receipt and the warehouse transfer. I’m not as big a fan of the connection of the raw material into the batch. It really does depend on, on your process and the actual equipment you’re using, but try to envision the person out on the floor, asking them to have a scan gun and scan that into the batch and, and still stay safe and keep the quality where you’re expecting it to be. I’m just not as big a fan of this transaction the consumption of the raw material as I am all the other transactions. So a way to work around that is to have the warehouse transfer into a bin or a site that is specific for that production area.

And then let the batch do it later. So on the screen is a screenshot of one of our screens of a lot selection. It’s really easy for somebody to go and pick the lots that were, especially if you’re only seeing the lots that have been moved into that bin, you can easily tell the system, go consume these lots into this batch.

And you’re done. That offloads the need for the requirement for an operator to have to be dealing with barcodes. But as soon as that inventory gets packaged or into whip, or kind of outside the process at the end of the batch, then back to barcode data collection makes a lot of sense there as well.

So basically, my takeaway on all this, or the thing I want to leave with you is when choose to either start lot trace or specifically do it with a computer. Think through the big transactions that you’ve got and try to identify how you’re going to be affecting the other steps down line.

And if you do it right, you’ll probably find that it’s somewhat of a push. Different people will be doing different things, recording differently, but you’re going to be able to get some critical mass. You’re going to be able to get some benefit from previous steps to help you in the subsequent steps.

Now in a simple batch, all I’m trying to show on this slide is, is that you’re going to start with your basic formula, but just remember, you’re going to end up with any number of lots coming out of it. It’s very common to be pulling multiple lots against a single batch. Now associating that lot to that batch and that becomes really important when we get to the actual lot trace itself. So what we’ve done so far is we’ve identified all the transactions where all material comes in, it gets transferred to production. It gets used in production, something gets put on hand and then we ship it out the door. All that data is now available to us, whether it be on bunch of pieces of paper or in a spreadsheet.

So this the lot trace it’s important to kind of have some key elements associated with this lot trace, you know, you’re going to need the ability to either start at a raw material lot, vendor called up and said, “Hey, I’m really sorry, but the lot we sent you last week, we’ve got a problem with it” and you’ll be able to follow material go all the way to the customers or go the other way. A customer calls up and says we have a problem and go all the way back again. You also need to make sure to if you deal with intermediates is the ability to be able to drill through multiple levels of production. You’re actually seeing that on the screen, on the right-hand side, that’s a multi-level lot trace that I’ve got in my demo environment, but you’ve got to be able to go upward and downward and also through multiple levels.

Once you have this trace, there was this connection of this data together, there are some key pieces of data you’re going to want. You need to know the ingredient consumption. In other words, what the quantity was, what the date was. Data like that as well as the resulting lot. Where did it go? And then also the origin or the destination number, the PO number, the invoice, etc.

So being able to connect that information into, in our case into the ERP like Microsoft Dynamics, being able to read that information and know that this lot went out on this invoice to this customer becomes pretty important. And this screen is basically just a quick snapshot of how we’re doing that in our application.

Now, the reason I’ve spent time on this lot trace is that once you have to have the lot trace in place. Now this becomes a pathway of data from raw material, all the way to the finished. And this is the extra part of lot trace it’s beyond what most people think about lot trace. So, we take a step back for just a second.

Let’s think about the various pieces of data that we have in our system. One of them I’m going to call lot attribute. You have a lot of raw material that comes in and it has, of course, a lot number and a quantity and a price and some things like that, but there’s also other information kind of metadata if you will, against that lot. You’ve got the supplier. Who did we buy it from? You’ve got things like a manufacturing date and expiration date and maybe even how it was transported to you. Was it in a refrigerated truck? Was it frozen, etcetera? But you have various pieces of information whether it be textual or numeric that can be tracked against this specific lot that is more than just the lot number itself. Most of us already have this data. Oftentimes it’s sitting around on pieces of paper and clipboards and things like that.

This is an example on the screen of how we are doing that. We have basically an unlimited number of lot attributes that can be set up. And for every inventory item you can say, here’s some other information that I want to track about this specific item. Additionally, we can look into quality data.

Most of us do in some form, do some quality. If frame-bound raw materials, you might rely on a certificate of analysis. You might do your own tests. You might have in-process whether it be formal tests or observations looking at how the product is performing through the process and having control points that if there’s a problem, we stop take corrective action and, and then move forward.

All this quality data is available somewhere. Again, sheets of paper, Excel worksheets, whatever. This is an example of our quality entry screen. Probably intuitive. There are the tests that we’ve got. It happens to be against our raw material a lot you’re looking at, but these are the various tests that we’ve got. The specifications as well as the results.

This can also be done for a batch. Now, this information is now available to be used and tied to this specific batch or to this specific lot. Then we also have got some other operational data. Now think in terms of line speeds, machine settings, crew sizes, all that kind of information can give you insights into the running of that specific batch.

So maybe the line was running faster than typical, or the oven was at a lower temperature, or maybe we had some type of operational problem going on. Now operators online can help paint the picture of what happened in this process, in this batch. This screen that you’re looking at is, is where we can record the results of a batch.

In this case, I’m prescribing them on formula entry here, but we can record the results on each individual batch ticket. So you can define here’s all the data I want to collect it. Isn’t like inventory. It’s not like quantities and lots, and it’s not quality. It’s more operational data.

So you have all of that. Now I guarantee most of us have got this data floating around. Again, on our side, we’re bringing it all into a database with one, one place to go look at it. So now we have all these islands or pockets of data. Most companies had it in some form or another spreadsheet, pieces of paper, whatever.

We have lot attributes that are defining the lots. We have operational data that’s telling us a little bit about the process that took place during the batch. And we have quality data with tested values and maybe even observations and any corrective action that was necessary to keep the batch going.

Most companies stop here. In other words, this data is pockets or islands of data that don’t really have a correlation to each other. With the lot trace, however, you’ve now got a skeleton or a backbone or a way to get from point A to point B or point C through the process and be able to start correlating this data and bringing it all together because that runs speed might affect some quality or a lot attribute like a brick’s content or something like that may affect any of the other operational parameters. So basically, what we’re thinking about is connecting different pieces of data together. I am presenting this as lot attributes, operational data, and quality data, but it could be any other pieces of data that you might have all being tied to an inventory item or to a batch, i.e., the lot into the batch going out to a customer on an outbound lot.

In Vicinity, we’ve connected all that data together. There are plenty of ways to do that, but this is how we chose to do it. We chose to allow users to jump in at any point and see any related data. So, you could jump in at a batch ticket and see everything else around it: what lots were used in it, what quality it was affected on it, what operational data was collected during that time. And it’s important to be able to see how one piece of information, one activity affects another piece like a QC test. Because once you understand the relationship, when the temperature is too high or the run speeds are off, it’s affecting these quality values or performance data or yield information, once you can understand the relationship of those, then you can start optimizing the process.

It’s more than just idle kind of information. It really becomes helpful to be able to get your formulas operating to the most efficient way in the most cost-effective way. This screen pulls all this information into one place. And if I would believe that this is where future improvements are going to lie.

Beyond just getting better prices for your raw materials or getting better equipment or things like that. But being able to understand this data and how it correlates with each other so that you can make intelligent, thoughtful positive changes in your process. And behind all this underlying data is that lot trace. It is that roadmap that gets you across all this data and is the glue that brings all this together.

So as the title implies, there’s more to lot trace than lot trace. Yes. You need lot trace for compliance reasons. Yes, you might want to be using it to, to win new customers. All of those are important things, but it’s also there to help you connect data that you otherwise probably were storing away on sheets of paper and somebody’s Excel spreadsheets trying to correlate this data together.

So I would challenge each of you to kind of look at what pockets of information you’ve got. How can you connect that data probably through a lot trace type functionality and how can you help make some better decisions for your organization?

So back to you, Dave. Okay. Thank you, Randy. I think we have time for a few questions.

Question: Would you start with lot tracing or quality before you connect that data together?

That’s a good question. I think it really kind of depends on the organization. Chances are you’ve got one or the other in place and try to leverage off that. Leverage off the thing that is, and if neither are done, automate that which is easy to automate first. Get that one in first.

So most of us are doing lot tracing already. You may not have a quality department that is tracking a lot of quality information in a database. In which case, if you’ve got lot trace in place then I’d probably go look at quality after that. But eventually the lot tracing is where it will all come together. So it kind of depends on the organization.

Question: What tools do you suggest in reporting quality data that is connected to lots?

Yeah. So bringing this data together in different sources like first off it needs to be electronic in some way in our environment, everything would be in a database, so that’s great. But in some cases, some data may be in one system and another data might be in another system and connecting that, honestly, isn’t as hard as people make it sound.

Excel is a wonderful tool for analyzing data. I’m not a big fan of it being a database, but I would really gear toward people, looking at using and leveraging the tools in Excel to reach into other sources of data. So, for example, Excel can read natively into databases, it can clearly read into other spreadsheets as well.

But using I’m a big fan of using Excel as a starting place for this, for analytics, not for databases. Also, kind of the big brother to that in my opinion, would be power BI, which is basically taking that and turning it into dashboards and making it available for people to see that information outside your organization, or maybe not necessarily in your building, through a browser. It’s really where I’m going with that. So I would really kind of look to leverage tools like Excel to get started with that.

Question: How do you suggest handling rework as it relates to lot traceability?

Yeah. So rework is an interesting thing. It really has to do with whether that lot left that batch and went into another batch. If you’re just simply taking some rework and reworking it back into that batch, simply from a lot trace perspective, it won’t have any impact. If, however, that lot is leaving this batch and going into another batch, like a traditional rework, then you’re going to need to make sure that you’ve got some way to identify that as a lot so it can then be the lot trace can continue into the next batch. So, I think it really kind of depends on what type of rework we’re really talking about. If it’s, if it’s in your closed system, not a big deal, at least from a lot trace perspective. It may have a quality challenge that, that I’m not really referring to here right now, but just from a lot trace, if it stays within that batch, you really don’t have a big issue, but if you’re reworking into another batch, then yeah, you need to get your lot trace going for that.

Question: What are some of the biggest challenges in starting lot traceability within a computer system?

Hmm. Well, you’re talking to a computer guy, so the software side itself isn’t a big challenge in my opinion. But I’m biased for sure. From my seat, the challenges that we see our clients go through is more organizational change is getting people okay with the concept that they’re going to have to record more. They spend more energy on getting the data, right. Rather than just letting it go and I’ll pick it up at the end of the month. With lot trace, you’re really going to have to be in your, a game on recording that kind of data.

So getting people to just relax a little bit, think about the transaction types and commit to doing it. That’s the biggest challenge. It’s more of a people challenge than it is necessarily a computer challenge. Barcode data collection is wonderful as long as your processes are under control. One of my good friends writes barcode software and says barcode data collection’s great. He says, ” it will screw things up at the speed of light”. You know, if you don’t have your processes under control, then you’ve really got a problem. So yeah, I think focus on the transactions, focus on the people and help them understand how, if you do it right up front in the long run, it’ll take you a lot less time and that’s true more than just food manufacturing but definitely, in this case, change management is probably the biggest challenge that we see in lot traceability.

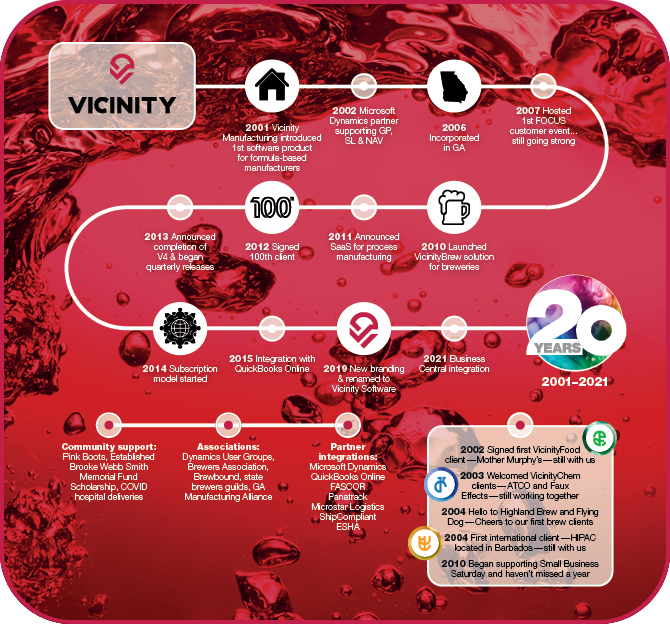

Take a look at the below milestones graphic to get a sense of our journey from 2001 to today.

Here are other articles you might like:

Release 4.38 – Highlights from a recent quarterly release

Intelligent Blends – success story

Increase profits by managing sample opportunities – VicinityFood