Keeping up with trends and introducing new product developments into the market is a constant for Food Manufacturing R&D departments.

The past few years have given us an influx of plant-based proteins used in traditional products as well as some unexpected ones like ice cream!

While protein has traditionally been sourced from animal-based products such as lean meats, eggs, and dairy, consumers are opening up to alternative options such as pea flour, almonds, chia seeds, quinoa, and spirulina, to name a few.

- Sales of plant-based meats sold to restaurants and other food service institutions reached $730 million in 2022, up 7.8% from the previous year, U.S. retail sales for plant-based meat — still the biggest overall category — remained flat at $1.4 billion last year.

Rises in one sector are typically balanced by a fall in another, many high sugar-based products are feeling the impacts of this market shift. To stay competitive, food manufacturers need to modify products to follow these trends or introduce new items to their product mix to help provide balance with growing segments.

How can having the right food manufacturing software in place help recipe or new product development team stay ahead of the curve?

Some of the central questions around formulation circle around marketing and the feasibility of the product in the market. Do these changes match market desires? How fast can you bring a new item to market?

Measuring the appeal of new and modified items touches on many variables, but the viability of a new product will come down to several business factors.

Do you have a system in place that can empower your brand to carry out new business-driving activities? How will production or R&D software help measure the impacts on your business?

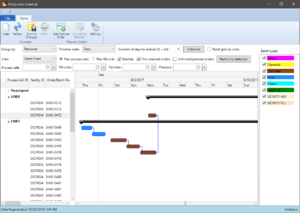

Tools to set structure around your formula trials, the feasibility of a new or altered recipe, access to historical formulas, and the ability to measure formula trials against each other: Many health or ingredient alternatives are accomplished via flavor layering to achieve similar consistency to the original product or ingredient properties – taste, mouthfeel/texture, etc. Having this data connected to your ERP or production system can help speed up analysis and set up access to historical formulas, and the ability to measure formula trials against each other. Here’s a quick list of 5 must-have R&D tools.

Scaling your formula production volume once you have a winning recipe can present a bit of trial and error in creating consistency as you increase the production volume of a test product for larger-scale distribution. Having a system to track different versions, ingredient substitutions, integrate nutritional values for label creation, and incorporate quality assurance values can speed up finalization.

Production tracking for recipe performance and overall impact: Batch yield is a great indicator of formula performance…how can I get the highest return from my raw material inputs? First, you need to understand your baseline measures. Learn more about how measuring batch yield can influence how you optimize production. Also, check out this case story from a premier dessert manufacturer who utilizes VicinityFood and was able to see lot tracing reduced from 4 hours to 4 minutes and accurate inventory controls saw reduced costs by 40%.

Calculating the cost of production: Having a complete picture of your total cost of goods sold, broken down by formula, brand or SKU is essential in setting a price that is in line with market standards, but also ensures the product provides a healthy margin. Understanding how product changes impact the rest of your business is essential in setting prices and validating new formulas long-term.

Calculating the cost of production: Having a complete picture of your total cost of goods sold, broken down by formula, brand or SKU is essential in setting a price that is in line with market standards, but also ensures the product provides a healthy margin. Understanding how product changes impact the rest of your business is essential in setting prices and validating new formulas long-term.

How do these changes impact and fit into the rest of your business operations?

How do the raw materials compare to the rest of your product lines? Does this create a challenge or possibly a bulk pricing opportunity for purchasing?

What is your production throughput? Are you able to produce more product in less time? Does this change in production take capacity away from other items in your product mix?

Having the right software to track key production elements can provide insights to take a new product launch to the next level and offer your business visibility into impacts across departments to measure the viability of new products within your product mix. Contact the Vicinity team today to learn how Vicinity Software may help your organization streamline overall production and stay on pace with market trends and formula development.